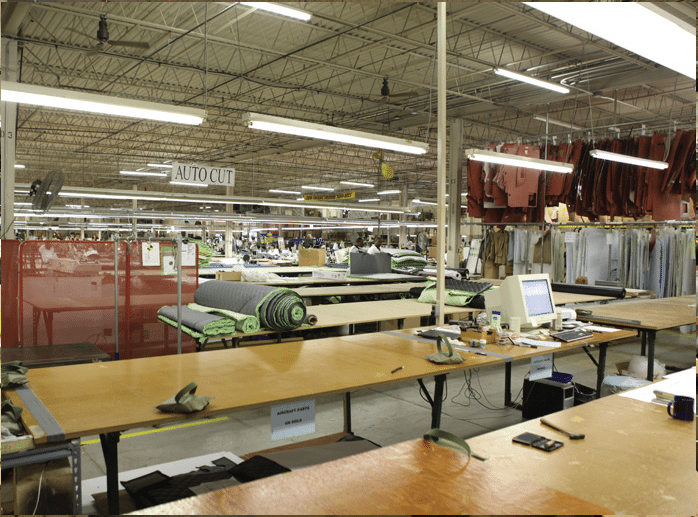

FOD & Safety Protective Products

While performing maintenance on their aircraft, mechanics are exposed to many hazards; including sharp edges, head-level antennas and access doors and various equipment (ladders, scissor lifts) blunt edges. The Air Line wanted to renew their commitment to Employee Safety and turned to Ehmke Manufacturing Company for help.