Challenge

The AC-130 gunship, in service since 1967, is one of the most heavily armed fixed wing aircraft in the NSWC arsenal. Although different variants of the aircraft maintain a variety of weapon systems, our company was called upon to find a solution to manage the overwhelming amount of spent shell casings expelled on the AC-130U “Spooky” aircraft. The AC-130U primarily utilizes a 105mm Howitzer cannon (the largest airborne gun in the world), twin 20mm Vulcan rotary cannons (7,200 rounds/MINUTE), a 25mm Gatling gun (1,800 rounds/min), and a 40mm Bofors cannon (100 rounds/min).

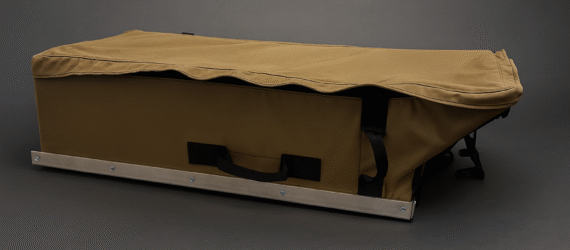

The need for onboard management of spent shells is critical during missions. The NSWC Special Operations Command called on our company through an engineering firm to design a portable solution that safely collects, stores and disposes of the spent shells to protect the flight crew from injury. Because Ehmke Manufacturing successfully outfitted the quilted interiors of the fleet of AC-130U aircraft, we were chosen as a sole-source to design and fabricate a multiple-wheeled bag solution. The requirement set forth by the NSWC called for an engineered solution designed with tight tolerances within a restricted space. Most importantly, the materials needed to perform under extreme temperatures, to be highly abrasion proof, and be constructed to capture and move heavy weights.